|  |

|---|---|

| Who is Kevin Mitnick? The picture that emerged after his arrest in Raleigh, N.C. last February was of a 31-year old computer programmer, who had been given a number of chances to get his life together but each time was seduced back to the dark side of the computer world. Kevin David Mitnick reached adolescence in suburban Los Angeles in the late 1970s, the same time the personal computer industry was exploding beyond its hobbyist roots. More on Kevin Mitnick | Fadia was educated at Delhi Public School. He started a website called "HackingTruths", which he claims was judged as the "second best hacking site in the world by the FBI". He claims that when he was 14, he trashed the front page of an Indian magazine's website. He then sent an e-mail to the editor confessing to the hack, suggesting counter measures. At 15, his book on Ethical Hacking made him the youngest author to be published by Macmillan India. More on Ankit Fadia |

Friday, October 19, 2007

hacking

Posted by

studentsview

at

11:52 PM

1 comments

![]()

Tuesday, October 16, 2007

India stand at fourth place in wind power

Wind power is the conversion of wind energy into more useful forms, usually electricity, using wind turbines. At the end of 2006, worldwide capacity of wind-powered generators was 74,223megawatts; although it currently produces just over 1% of world-wide electricity use. it accounts for approximately 20% of electricity use in Denmark, 9% in Spain, and 7% in Germany.Globally, wind power generation more than quadrupled between 2000 and 2006.

Most modern wind power is generated in the form of electricity by converting the rotation of turbine blades into electrical current by means of an electrical generator. In windmills (a much older technology), wind energy is used to turn mechanical machinery to do physical work, such as crushing grain or pumping water.

Wind energy is plentiful, renewable, widely distributed, clean, and reduces toxic atmospheric and green house emmission if used to replace fossil-fuel-derived electricity. The intermittency of wind seldom creates problems when using wind power at low to moderate penetration levels.

India ranks 4th in the world with a total wind power capacity of 6,270 MW in 2006. Wind power generates 3% of all electricity produced in India. The World Wind Energy Conference in New Delhi in November 2006 has given additional impetus to the Indian wind industry. The windfarm near Muppandal, India, provides an impoverished village with energy for work.India-based Suzlon Energy is one of the world's largest wind turbine manufacturers.

Posted by

Prabal Aggarwal

at

8:15 AM

0

comments

![]()

Labels: Power Engineering

Wednesday, October 10, 2007

Mechatronics

Experts are of the opinion that future mechanical,electrical ,computer science and IT have to deal with mechatronics or face the possibility of becoming out dated. Mechatronics are now a days used in manufacture of cars by use of electronic engine management systems ,collision detection,global positioning system etc.Research and development potential in mechatronics includes areas such as space technology, especially in the wake use of robots for space exploration.

Another variant of mechatronics is boimechatronics which is an applied interdisciplinary science that aims to integrate mechanical elements in human body,both for therapeutic uses and for augmentation of existing abilities.is includes aspectsof biology ,mechanics and electronics.

Posted by

GOUTHAM.K

at

10:07 AM

0

comments

![]()

Labels: Mechanical Engineering

Tuesday, October 9, 2007

state level technical symposium in bio informatics

hi friends,

I am very glad to inform you people that there is a state level technical symposium "BIOSILICON" held in bharath university,chennai on 12th oct.any interested candidate can paticipate and present their paper and all the participants will be awarded with the participation certificate.if you are interested plz reply me back to ksowmya20@gmail.com for the topics. Hoping for the positive reply.

Posted by

sowmya

at

6:09 AM

1 comments

![]()

Thursday, September 27, 2007

Civil Engg.

Civil Engineering is a profession which caters to the civic needs of humans such as shelter, water, transportation, etc. It essentially deals with design, construction and maintenance of the systems which cater to the human needs stated above. Some of these are buildings, bridges, roads, dams, towers, etc.

Civil Engineering can broadly be defined into the following divisions

1. Structural Engineering: One of the most interesting fields of civil engg. (according to me) deals with the design of structures. Structural engineers may work in tandem with architects in the design process. Nowadays the design is done mostly in softwares but still the role of a structural designer cannot be underestimated.

2. Building Technology and Construction Management: This involves the actual execution process. After software, construction sector is the one which has been having the maximum boom in the last five years. Construction is no more only brick and mortar. It requires high level of managerial skills along with the basic civil engg. Knowledge.

3. Geotechnical Engineering: Geotechnical engineers deal with the soil as the name suggests. They are involved in design and construction of foundation systems. Nowadays there are companies dedicated only for Geotech works as the foundation systems are getting more and more complicated.

4. Transportation Engineering: It can again be divided into two categories one which deals with the design and construction of roads and other which deals with the design of road networks (they decide where to have a flyover, signal timings etc.). If you want to go to US for higher studies this is the field to go into. There is lot of research going on in US in transportation engineering and you can funding pretty easily.

5.Environmental and Water resources Engineering: This division deals with dams, irrigation projects, drinking water supply, waste water treatment, etc. Environmental Engg is one more option for students who want to go abroad for further studies. There is a lot of funding in environmental engg not only in US but also in Europe.

Posted by

vikas

at

8:14 AM

0

comments

![]()

Labels: civil engineeering

Tuesday, September 25, 2007

Montevina: The NExT Centrino to be launched by Intel

Intel had been waiting for the right time to unravel it’s brand new mobile platform. Intel calls it the Montevina platform. Montevina is the fifth generation Centrino platform, on which you not only get integrated WiMAX capabilities, but also benefit from chip-level support for both the upcoming laser-disc technologies, Blu-Ray and HD DVD. This almost aggregates the ongoing “format war”, since dual support for the formats is being preferred by an increasing number of manufacturers. It is good for the consumers, but Sony will be disappointed as this is going to nullify their efforts to make Blu-Ray the monarch.

Intel had been waiting for the right time to unravel it’s brand new mobile platform. Intel calls it the Montevina platform. Montevina is the fifth generation Centrino platform, on which you not only get integrated WiMAX capabilities, but also benefit from chip-level support for both the upcoming laser-disc technologies, Blu-Ray and HD DVD. This almost aggregates the ongoing “format war”, since dual support for the formats is being preferred by an increasing number of manufacturers. It is good for the consumers, but Sony will be disappointed as this is going to nullify their efforts to make Blu-Ray the monarch.  Displayed at the Intel Developer Forum for the first time, the Montevina mobile computing platform has been specially designed to take over the company’s highly successful Santa Rosa notebook architecture. Montevina will host the new 45nm Penryn processor architecture, which means integrated WiMAX capabilities but could not opt for one choice in the ongoing high definition format war. Consumers will win in the end with this approach, as they will be able to watch movies that are exclusive to either format, while Toshiba and Sony sit down, bubbling in a corner.

Displayed at the Intel Developer Forum for the first time, the Montevina mobile computing platform has been specially designed to take over the company’s highly successful Santa Rosa notebook architecture. Montevina will host the new 45nm Penryn processor architecture, which means integrated WiMAX capabilities but could not opt for one choice in the ongoing high definition format war. Consumers will win in the end with this approach, as they will be able to watch movies that are exclusive to either format, while Toshiba and Sony sit down, bubbling in a corner.

This is a very appreciable effort from the Intel factories, since it is a chip manufacturer and to offer such support for both disc formats is simply a burden as the two formats commonly share the same codecs: H.264, VC9, and MPEG-2. It is this onboard support for either of the two platform that makes system makers choose either HD DVD or Blu-ray capability, or even both.

Seen overall, this HD format hype shall be easily overtaken by the on-board WiMax support that Montevina caters to.

by Mitesh Ashar

Posted by

Mitesh Ashar

at

9:55 AM

0

comments

![]()

Labels: Computer Engineering, Electonics Engineering, intel, processors

Saturday, September 22, 2007

Current electricity generation in india

- Coal based thermal power is 70,682 MW which contributes 53.3 % of total insatalled base· Gas Based

- Thermal Power is 13,691 MW which contributes around 11% of thermal based power·

- Oil Based Thermal Power contributes around 1% of total thermal power

Current installed base of Thermal Power is 85,575.84 MW which comes to 64.7% of total installed capacity from all sourses.

Hydro power plants

India was one of the poineering states in establishing hydro power plants . Current installed base of Hydro Power is 34,654 MW which comes to 26.2% of total installed capacity. Today Hydro sector has turbines as large as 250 MW and single stage projects as big as 1500 MW Nathpa Jhakri .

Nuclear Power Plants

Currently 17 Nuclear Power reactors produce 4,120 MW which comes to 3.1% of total installed base.

Current installed base of Renewable Power is 6,761 MW which comes to 5.9% of total installed base.

As per data (as of May 2006) shared by Power Ministry, addition power of 19,680 MW will be added in remaining period of 10'th Five Year Plan (2002-2007).

Posted by

Prabal Aggarwal

at

6:21 AM

1 comments

![]()

Labels: Power Engineering

Wednesday, September 19, 2007

OEE-Overall Equipment Effectiveness

- Lets assume that there is a student of Engineering, who has 365 days in the year.

- Out of 365 days lets assume that 100 days are for holidays, as no student should study for 365 days. Then 265 days are left. This is known as Loading Time, while 100 days are known as Not Scheduled Time.

- Now, out of planned 265 days of working, student fells ill for aroun 15 days. Now, this gives us actually 250 days, where the student actually worked, and is known as Running Time. While the 15 days are known as Idle Time.

- Now, lets assume that the student claims that at his efficient or effective state of mind an health he can complete 80 pages of a book per day. So, this can be considered as Theoretical Output that is expected during the Running time. So, in this case it would be 250x80=20000 pages in the year. But, actually we found that he has read only 15000 pages. The reasons could be several that reduced his efficiency and effectivenes. So, 15000 pages, is known as Actual Output.

- Now, at the end of the year, teacher took a test of the student. The test was out of 15000 pages he studied during the year. As, the student has read it effectively and efficiently he should have got 100 marks out of 100. But, he got only 70 marks. Now, whats the reason. It means that out of 15000 pages he read only 70% properly. Other 30% was bad quality reading. So, he read only 10500 pages properly and the 4500 pages not properly. So, 10500 can be said as Good Output.

So, now we will calculate the OEE of student during the considered year. It will be comprised of following elements

- Availability i.e. Running Time/Loading Time or we can say actually followed time table w.r.t. planned time table.

- Speed Efficiency i.e. Actual Output/Theoretical output.

- Quality Efficiency i.e. Good Output/Actual Output.

Or if you notice carefully, in the above diagram we have just calculated Good Output/Loading Time.

Posted by

Prabal Aggarwal

at

3:14 AM

1 comments

![]()

Labels: Industrial Engineering, Mechanical Engineering, Power Engineering, Production Engineering

Sunday, September 16, 2007

Electrical Engineering

The term electrical engineering may or may not encompass electronic engineering. Where a distinction is made, electrical engineering is considered to deal with the problems associated with large-scale electrical systems such as power transmission and motor control, whereas electronic engineering deals with the study of small-scale electronic systems including computers and integrated circuits. Another way of looking at the distinction is that electrical engineers are usually concerned with using electricity to transmit energy, while electronics engineers are concerned with using electricity to transmit information.

Posted by

studentsview

at

7:04 AM

5

comments

![]()

Labels: Electrical Engineering

Saturday, September 15, 2007

Introduction to RFID in supply chain

Research firm Gartner, Inc. states: “The use of RFID to capitalize on data flow in global supply chains could be one of the most-significant developments since enterprises first explicitly recognized the importance of information flow in the supply chain.”

Squeezing cost and inefficiency out of the supply chain has been one of the recurring mantras of the industrialized world for the past 50 years. The concept, as we would recognize it, has its roots in the Toyota Production System (TPS) of the 1950s and has been refined and improved significantly over the years to the point where one might expect that the most sophisticated devotees today have optimized their supply chains.

The journey towards perfection, however, never ends. In the very near future, the adoption of sensor-based Radio Frequency Identification (RFID) technology will allow the creation of the real-time, sensor-connected manufacturing plant. By adding RFID tags to every product, tool, resource and item of materials handling equipment, manufacturers will be able to get better demand signals from customers and the market. RFID will have a significant impact on every facet of supply chain management—from the mundane, such as moving goods through loading docks, to the complex, such as managing terabytes of data as information about goods on hand is collected in real time.

RFID is a technology that uses radio waves to identify objects automatically. The applications of RFID have been found in all kinds of consumer products and industrial equipment. RFID, which has the same purpose as a bar code, provides a unique identifier for the objects. The most significant advantage of RFID over the bar code is that the RFID does not have to be positioned precisely and can function approximately 20 feet from the scanner. RFID technology not only can help businesses satisfy customer requirement, but also increase productivity to stay competitive.

RFID technologies hold the promise of closing some of the information gaps in the supply chain, especially in retailing and logistics. As a mobile technology, RFID can enable “process freedoms” and real-time visibility into supply chains. RFID promises to revolutionise supply chains and usher in a new era of cost savings, efficiency and business intelligence. The potential applications are vast as it is relevant to any organisation engaged in the production, movement or sale of physical goods. This includes retailers, distributors, logistics service providers, manufacturers and their entire supplier base, hospitals and pharmaceuticals companies, and the entire food chain.

Posted by

ViruS

at

12:00 AM

1 comments

![]()

Labels: RFID, Supply Chain Management

Friday, September 14, 2007

CMMI

ABSTRACT

“Understanding how software works will help to know how it can fail”

Abhishesh Kumar Sharma (AKS)

There are always these three questions going in the mind of any software implementers [19]:

Why is it so expensive to support and maintain my software products?

What is the reliability of our product?

What is the average cost of one software bug?

Software development organizations do not respond well to the process improvement innovations related to software development. Fear surrounds the thought of trying something new; this fear is accentuated by constant pressure to produce the product on time and within budget. Until recently, the vast majority of software companies did not view software development process management and improvement to be of strategic importance to the future of the company. Process improvement and its relationship to software quality, cost, and ability to meet schedules were never considered to be either useful weapons or, very often, differentiating factors against the competition. Nonetheless, a well-managed software development process can be viewed as an iterative process of information exchange and allows software development organizations a clear view and understanding of available information, providing a foundation for analysis and management of the software process based on hard facts and not vague assumptions. To be able to withstand the pressure of competition, to save money, and to improve the quality of production software, a progressive software development organization needs to realize the necessity for implementing and managing an efficient and effective software development process [16].

This paper presents the conceptual model of the Capability Maturity Model Integration (CMMI) which is being examined of multiple relationships between measurable process quantities and characteristics. The quality in software project management has evolved over a period of time and CMM has matured to a significant level that almost all software companies follows this model. The next big model used is the ISO for the quality but CMMI has upper hand in advancement of tools and techniques [22].

Although CMMI has matured to enormous level but still many short coming has been found while following the procedure mentioned in the CMMI technical specification. Lots of research has been done in this upcoming field but still there is lot of scope for improvement hence this paper is going to discuss the shortcomings of CMMI and will provide many new tools to help overcome these problems.

The concept of system thinking has been used so that the various ideas will focus on the relationships between the parts forming a purposeful whole [3, 6, 11]. The concept of system dynamics has been incorporated as that will give the continuous view of events. Feedback from the external environment has formed the integral part of the model development. Organizations will be able to design, build, and implement high-quality software products in spite of unexpected organizational and personnel changes, implementation of new technologies, or changes in customer requirements.

Posted by

Abhishesh Kumar Sharma

at

10:48 PM

1 comments

![]()

Labels: Computer Engineering, Quality Engineering

An Overview of Nuclear Energy

Safety

From the beginning, safety of nuclear reactors has been a very high priority in their design and engineering. About one third of the cost of a typical reactor is due to safety systems and structures. The Chernobyl accident in 1986 was a reminder of the importance of this, whereas the Three Mile Island accident in 1979 showed that conventional safety systems work.

Economics

Nuclear power reactors are expensive to build but relatively cheap to operate. Their economic competitiveness thus depends on keeping construction to schedule so that capital costs do not blow out, and then operating them at reasonably high capacity over many years. By way of contrast, gas-fired power plants are very cheap and quick to build, but relatively very expensive to operate due to the cost of their fuel. With rising gas prices, and the high cost of moving coal long distances, nuclear plants are generally competitive with both gas and coal in most parts of the world, and becoming more so.

Wastes

Nuclear power produces wastes, which are restricted and managed, with the cost of this being met by the electricity customer at the time. It does not produce any significant wastes, which are dispersed to the environment. It therefore avoids contributing to increased carbon dioxide levels in the atmosphere.

Radiation

Ionizing radiation, such as occurs from uranium ores and nuclear wastes, is part of our human environment, and always has been so. At high levels it is hazardous, but at low levels it is harmless. Considerable effort is devoted to ensuring that those working with nuclear power are not exposed to harmful levels of radiation from it, and standards for the general public are set about 20 times lower still, well below the levels normally experienced by any of us from natural

Avoiding weapons proliferation

The initial development of atomic energy during and immediately after the Second World War was to produce bombs. An early concern when the atom was harnessed for controlled civil use was that this nuclear power should not enable more countries to acquire nuclear weapons. Through the United Nations, procedures were set up to ensure this, and in fact they have been perhaps the most eye-catching success of that body. No nuclear materials such as uranium from the civil nuclear fuel cycle have ever been diverted to make weapons. In fact today the whole picture is reversed in that a lot of military uranium is being brought into the civil nuclear fuel cycle to make electricity, which is widely seen as a positive development, unimaginable 40 years ago.

Posted by

Prabal Aggarwal

at

9:09 AM

0

comments

![]()

Labels: Nuclear Energy, Power Engineering

Saturday, September 8, 2007

introduction to bioinformatics

Friends this is 21st century,every century had its own marking in the educational history.tn the same way this century is named as the INFORMATIC ERA.The two most important and the booming fields informatics and biology are combined in a very appreciable manner to form this bio informatics.

Bioinformatics involve the use of techniques including applied mathematics, informatics, statistics, computer science, artificial intelligence, chemistry, and biochemistry to solve biological problems usually on the molecular level. Research in computational biology often overlaps with systems biology. Major research efforts in the field include sequence alignment, gene finding, genome assembly, protein structure alignment, protein structure prediction, prediction of gene expression and protein-protein interactions, and the modeling of evolution.

The terms bioinformatics and computational biology are often used interchangeably. However bioinformatics more properly refers to the creation and advancement of algorithms, computational and statistical techniques, and theory to solve formal and practical problems inspired from the management and analysis of biological data. Computational biology, on the other hand, refers to hypothesis-driven investigation of a specific biological problem using computers, carried out with experimental or simulated data, with the primary goal of discovery and the advancement of biological knowledge. Put more simply, bioinformatics is concerned with the information while computational biology is concerned with the hypotheses. A similar distinction is made by National Institutes of Health in their working definitions of Bioinformatics and Computational Biology, where it is further emphasized that there is a tight coupling of developments and knowledge between the more hypothesis-driven research in computational biology and technique-driven research in bioinformatics. Bioinformatics is also often specified as an applied subfield of the more general discipline of Biomedical informatics.

There are many databases and sites which deals with bio informatics..The most important and the basic one is the NCBI database,which help us in having the basic information about the proteins,chemicals,3d structures etc.The site for NCBI is

http://www.ncbi.nlm.nih.gov/.

there are many sites and softwares ,useful which i’l be posting them in a short while.

Posted by

sowmya

at

10:17 AM

4

comments

![]()

Labels: Bio informatics

EE

My dear friends this is my first article,in this i gave you some information about the fieid of electricals and electronics.

The Field

Electrical and electronics engineers conduct research, and

design, develop, test, and oversee the development of

electronic systems and the manufacture of electrical and

electronic equipment and devices.

From the global positioning system that can continuously

provide the location of a vehicle to giant electric power

generators, electrical and electronics engineers are

responsible for a wide range of technologies. Electrical and

electronics engineers design, develop, test, and supervise

the manufacture of electrical and electronic equipment.

Some of this equipment includes broadcast and communications systems; electric motors,

machinery controls, lighting, and wiring in buildings, automobiles, aircraft, and radar and

navigation systems; and power generating, controlling, and transmission devices used by

electric utilities. Many electrical and electronics engineers also work in areas closely related to

computers.

Many authorities believe that the two fields of "electrical

and electronics engineering" and "computer science and

engineering" have now established separate identities,

although they still have much in common. Because of the

breadth of the field, however, general statements about

"electrical engineering" include electrical, electronics,

computer engineering, computer science, and related

areas of arts and sciences in the broadest context and

application.

Posted by

studentsview

at

6:06 AM

0

comments

![]()

Labels: Electonics Engineering

Thursday, September 6, 2007

JIT-Jidoka (Autonomation)

Now, how this signal is generated. In the traditional automobile environment, the operator or the authorized person on the defect producing station pulls the hanging rope (above the station). This rope is connected to all the lines. And pulling the rope from any point leads to the shut down of all the connected lines.

The method of generating signal was modified to electronic means, when the rope was replaced by a button available on all the stations. This button, when pressed via common electrical supply shuts down all the connecting production lines. And immediately, the Andon board, with all the stations labeled on it, starts indicating that problem is occurring on a particular station. And recently, with the improvement of Internet and Information Technology this is done by use of sophisticated electronics and software.

This system was enhanced and implemented to an extent, that even the supplier and customer plants were sometimes stopped by the signal.

Posted by

Prabal Aggarwal

at

1:40 PM

4

comments

![]()

Labels: Industrial Engineering, Just In Time, Mechanical Engineering, Production Engineering

ONE LAKH CAR CONCEPT

Ratan tata had a dream of substituting two wheelers on road . this developed into emergence of a ONE LAKH CAR CONCEPT, which is said as the chairman’s parting gift to the Indian auto industry.

The criterion was simple, to produce a small car with four doors, cheap to run and conseable to produced in different parts of the country.

Beginning with styling , this car could be said as funky, starting from the zing DNA which was modeled on the smart and looked much like the Daimler Chrysler micro-mini ,the car is now evolved. It sports a sleek, but blunt front end which is reminiscent of the recent of recently launched ZEN ESTILO .

The engine is at the back thus there will be little space behind the back seat and the rear hatch. So luggage space will be premium and be one of the draw backs os the car. The rear hatch will provide access to the engine which will be below the rear seat, the folded over seat presents the luggage carrying option.

It’s a two cylinder engine and 660cc for a petrol engine and 700 engine. The company is planning to launch the petrol engine and later the diesel one.The diesel engine will be two cylinder common rail engine with a specially designed injection system developed by BOSCH for low cost two cylinder engines .Mileage has been reportedly to be 26kmpl in tata internal test and company is trying to increase it to 30. we can expect around 24kmpl on the road .

The two dorrs on the either side are tiny,especially the rear ones. How ever they offer comfortable ingress/egress considering the height of the car. Considering the height of make and rear engine,inside spacing is premium make. One thing is sure, it’s a city car and could be out of place on high ways.

The price is expected to lie between 1.1 -1.25 lakh

Posted by

GOUTHAM.K

at

11:52 AM

1 comments

![]()

Labels: Automobiles, Mechanical Engineering

Monday, September 3, 2007

MECHANICAL ENGINEERING

A mechanical engineer had ,has and will have a good demand.

Each and every industry begin put up needs a mechanical engineer and its a VAST subject.

This particular branch has many sub divisions ,which may be broadly divided into

1)Heat& thermodynamics.

2)Manufacturing.

3)Machine design.

4)Machines.

HEAT & THERMODYNAMICS

This can be defined as the heart of the mechanical engineering.

This mainly deals with the heat which may be further divided into

a)Refrigeration and Air conditioning, which may be further divided into crogenics (dealing with temperatures below 120k)

b)Combustion :This deals all the combustion processes taking place in engines.

c) Heat transfer:This deals with processes like convection,conduction,radiation which are being used in the development of solar energy concepts,thermal power plant engineering etc.

d)GAS dynamics : This particular area is developing htese days and lot of reasearch is going on these days in computational fluid dynamics.

Manufacturing:

This is another important part of the mechanical engineering mainly dealing with the various conventional and modern methods of producing machine parts and processing techniques.

This you can say is a kind of dry subject where u come across various machines used for producing parts.

In this area the importance is given for developing methods to get parts machined parts with greater surface finish and quality,reducing wastes during producing parts,developing new modern methods for solving the problem of huge waste.

The modern methods include processes of converting one form of energy to another in order ot get parts machined .ex:using water jets,lasers,electron beams etc to remove material.

A lot of research is going on these modern methods which is quite interesting..

Machine design:

In the current world a lot of credit is begin given to manufacture things with grater compactness.This is what is begin dealt in this part.

this has huge huge demand ,like designing of cars of very small size.

This mainly deals with the designing of parts to work under particular constraints, taking decisions like which material can be used to replace a particular material for many reasons like weight constraint,thermal behavior etc.

To conclude this is a very interesting area with a lot of thing to be explored

Machines:

This part may be said to contain many things which we can see in daily life having greater usage and importance like automobiles,fans,turbines etc.

This part will provide you with the basic concepts and working principles of the machines.This one too is an interesting area with a lot to be explored.

Posted by

GOUTHAM.K

at

11:55 AM

1 comments

![]()

Labels: Mechanical Engineering

Saturday, September 1, 2007

Patents uncovered!!!

Posted by

Prabal Aggarwal

at

3:56 AM

0

comments

![]()

Labels: Innovation, Patents, Research

Wednesday, August 29, 2007

Design Engineer-Careers in Mechanical Engineering

Posted by

Prabal Aggarwal

at

8:32 AM

6

comments

![]()

Labels: Careers, Mechanical Engineering

Tuesday, August 21, 2007

Careers in Civil Engineering!!!

We all know that construction sector is booming like anything and there is lot of careers for civil engineers in this. As civil engineer I want to tell all those people who want to make their careers in construction industry.

Some of the Careers are mentioned below:

·Design Engineer: A person after passing from engineering college can join any construction industry in their design department as a design engineer. The work profile of a person is Design the structural design of any structures like Dams, Buildings, Roads, cooling towers etc depends upon the company a person joins.

·Site Engineer; In this a person send to actual construction project of a company as site engineer where a person have to manage lot of things like labors, materials etc and by seeing the drawing sent by design department make the structure.

·Quality control Engineer: In this person looking towards the quality aspects of site which includes material testing like concrete, sand, cement and aggregates etc and also looking the site activities whether everything is going on as per required quality of customers/clients. Also, person gets responsibility of making a bill, which he has to get pass from clients every month.

·Safety officer: In this person involved in looking after the safety aspects of site like safety of labors, electrical equipments related safety etc.

Posted by

yogesh

at

10:29 AM

0

comments

![]()

Labels: Careers, civil engineeering

The Dilemma of a Computer or IT engineer.

Posted by

ViruS

at

7:18 AM

1 comments

![]()

Labels: Careers, Computer Engineering

Saturday, August 18, 2007

Careers in Mechanical Engineering

This is my first article on the series. The series will be dedicated to the career options for engineers in the field of Mechanical Engineering.

Profile No. 1

Production Engineer

Well I am writing this on the basis of my experience as Production Engineer in Subros Ltd and Philips Electronics India Ltd

The role is of handling Production lines anywhere like in the field of Automobiles one handles assembly lines, machining lines, heat treatment lines, sheet metal lines, tube bending lines, etc.

The career path is normally a fresher is hired ( campus or off campus) as GET( Graduate Engineer Trainee). And the first few months goes to get accustomed to machinery. Especially in Japanese companies, it is ensured that engineers are trained to handle machines themselves. Then the Engineer comes into role of coordination. This includes, to delegate and monitor tasks of operators as per the scheducle given by PPC ( Production Planning & Control). Then to coordinate with Maintenance Deptt, Quality Deptt, Stores Deptt, Purchase Deptt, HR deptt and virtually every department.

This is most critical profile in production based companies, because here is the actual operations are conducted, others are support functions.

The issues one has to deal with are :

- Material Shortages

- Machine Failure

- Bad Quality

- Audits

- Thefts

- Absentism

- Union Problems

- Accidents

- Production Targets Failure

- Overtime

But, as the pressure is high so are the rewards. Production Engineers gets maximum increments and faster growth. Normally these are the people, who become Plant Heads, Operations Head and finally CEO's

The package starts in SME's is around 1.8 lac/annum and grows to 5 in next 3 years. After that it depends on the person's performance and the career path he has created for himself. Apart from money, this is the field for leaders, who have dominant and assertive personalities. They work like generals of army in the field.

My suggestion to everyone who wants to build career in Mechanical Engineering is spend at least 6 months in Production Department. The learning will be actual operations, around which the whole company revolves. So, once a person has been through this experience, he can work in any department keeping the actual situations in mind.

It will be good, if you read this article then comment on it. It will motivate me to write more in the series.

Posted by

Prabal Aggarwal

at

12:00 PM

5

comments

![]()

Labels: Careers, Mechanical Engineering, Production Engineering

Voltage Controlled Oscillators

What are voltage controlled oscillators?

The voltage controlled oscillator which is more commonly known, a vco, is an oscillator which works on the principal of variable capacitance or tuning with a varactor diode. The voltage controlled oscillator is tuned across its band by a "clean" dc voltage applied to the varactor diode to vary the net capacitance applied to the tuned circuit.

What are Varactor or Tuning Diodes

These types of diodes work on the principle that all diodes exhibit some capacitance. When the voltage applied across the diodes changes the capacitance developed across it also changes.

Temperature compensated voltage controlled oscillator

A VCO with temperature compensation is achieved using reverse biased diodes. The VCO includes an amplifier that provides the required signal gain, a resonator tank circuit that provides the required phase shift, and at least one frequency tuning circuit for tuning the frequency of the oscillator signal. Each frequency tuning circuit includes at least one tuning capacitor and at least one MOS pass transistor that connects or disconnects the tuning capacitor(s) to/from the resonator tank circuit. Each reverse biased diode may be a parasitic diode that is formed at a drain or source junction of a MOS transistor. The reverse biased diodes have capacitance that can be controlled by a reverse bias voltage to compensate for drift in the VCO oscillation frequency over temperature.

Posted by

Abhishesh Kumar Sharma

at

2:07 AM

0

comments

![]()

Thursday, August 16, 2007

Kanban

This is my second article of the series of Toyota Production System on this blog. I m not making it very elaborate and cumbersome. For more details there is lot of literature available on the net. My only objective in writing this article is to give the jist of the methodology and to share my experiences with the readers.

What is Kanban?

Kanban is a critical element of Toyota Production System, by acting as enabler to JIT. It was developed in Toyota Motor Corporation in Japan during 1950’s. Now it is a very popular tool in lean manufacturing.

Essentially, the most important role Kanban plays by enforcing and checking Pull System in manufacturing. Literal meaning of Kanban comes from Kan- card, Ban- signal. So, it’s a information system employing cards that enables and checks the usage of Pull System.

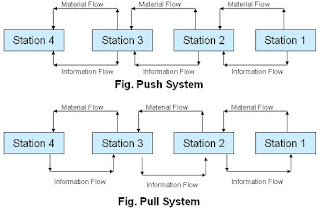

Pull & Push System

Without taking too much length of the article I will briefly explain Pull and Push System. Lets suppose there are four stations in an assembly line as shown in the fig’s. Station 1 is the first station and feeds material to the second station and so on.

In the pull system, the production schedule is given to the station 1. The station 1 accordingly makes the first component and pushes it to the station 2 and so on. In this way, along with the material flow station 1 is giving the information target also to the station 2, that how many components it needs to make.

In the push system, the production schedule is given to the station 4. the station 4 demands the number of components required from station 3 and so on. In this way the information is passed on from station 4 to station 3, that how many components it needs to make.

The push system is good when the certainty is the system is high, but normally its not so. Normally there is lot of uncertainties like change in demand, machine breakdowns, defective components, etc. This uncertainty leads to building up of inventory at every station. While in the case of pull system, actually the customer is driving the demand, by feeding the information of limited time period to the station 4. This enables the system to be flexible and more responsive to the market demands. The pull system, enforces that if one station is out of order then the whole line will stop example : if station 3 breaks down, then it won’t be able to supply to station 4 and it will stop and it won’t demand anything from station 2 and it will stop. This leads to reduced inventory at every step, which liberates the cost stuck in the inventories.

So, there should be a system that enables the pull system. Here Kanban comes into picture.

How Kanban works?

The simplest method used for Kanban is Dual Kanban. The elements of this system are :

- Production-ordering Kanban Card

- Withdrawal Kanban Card

- Kanban Post

A Production-ordering Kanban - specifies the kind and quantity of product which the preceding process must produce. The one illustrated (right) shows that the machining process SB-8 must produce the crankshaft for the car type SX50BC-150. The crankshaft produced should be placed at store F26-18. The production-ordering Kanban is often called an in-process Kanban or simply a production Kanban.

A Withdrawal Kanban - specifies the kind and quantity of product which a manufacturing process should withdraw from a preceding process. The withdrawal Kanban illustrated (right) shows that the preceding process which makes this part is forging, and the person carrying this Kanban from the subsequent process must go to position B-2 of the forging department to withdraw drive pinions. Each box of drive pinions contains 20 units and the shape of the box is `B'. This Kanban is the 4th of 8 issued. The item back number is an abbreviation of the item.

Kanban Post - Each process (area, cell) on the production line has two Kanban `post-boxes', one for withdrawal and one for production-ordering Kanbans.

Using Kanbans on a production line

At regular intervals a worker takes withdrawal Kanbans that have accumulated in his process post-box, and any empty pallets, to the location where finished parts (components, assemblies) from the preceding process are stored. Each full pallet has attached to it one or more production-ordering Kanbans which he removes and puts in the appropriate post-box belonging to the process that produced the parts. The worker now attaches a withdrawal Kanban to the pallet and takes it back to his own process area. When this new pallet begins to be used, its withdrawal Kanban is put back into the withdrawal post-box. At each process on the line, production-ordering Kanbans are periodically removed from their post-box and used to define what parts and quantities to produce next.

Enablers for Kanban are Quality Assurance and Production Smoothing as can be seen in this fig. If these things are not followed instead of becoming a boon to company Kanban becomes headache. I myself faced this problem when I designed Kanban System in one of the companies I worked for. But the moment I enforced Quality Assurance and Production Smoothing, the Kanban was able to play its meant role. I designed the system so that we are able to avoid the pilferation of material on the assembly lines. The pilferation, lead to inaccurate data punching in ERP software of SAP. The problem was that we were following push system. The worers were getting material more than required for the particular shift. This lead them to neglect the material falling on the shopfloor. The material which fell down was never picked by them, but by sweeper landing it to dustbins. So, actually the ERP was showing that the material of 100 assemblies was there, but it was of only 90. Now this inaccuracy of data, lead to backfire of whole Supply Chain. The stores were not aware that they are not storing enough material to support the production, so they didn’t order to vendors. Vendors didn’t knew that they have to produce this much supply components, so the vendor didn’t plan. But our customer has to be satiated at any cost. So, the result was use of defective parts, stealing parts from other lines, pressurizing vendors to produce more than its capacity. This chain of activities lead to the firefighting in all the related departments like PPC( Production Planning and Control), Production, Purchase, Stores, Vendors and so on. But the core reason was pilferage or push system. So, I proposed this to my company. And fortunately, I was given project to implement it. I studied around eight companies for designing it including Maruti Udyog Limited, Toyota, GE and others. Finally, when we implemented it, the results were simply mind blowing. I never thought that it could be so powerful. My only aim was short sited that is to check material pilferage. But the results were that the inventory of 48 hours on shop floor got reduced to 4 hours, production doubled, manpower was cut by 25 %, production incharge who earlier was always fighting for material on shopfloor didn’t need to go to shop floor for a week. This was one of the major turning point in my life. And I came to understand and appreciate the power of Toyota Production System or Lean Manufacturing and till now directly or indirectly I m pursuing career in it.

I hope the article would be helpful to the readers. Wait for next article of the series by me.

Posted by

Prabal Aggarwal

at

10:17 AM

0

comments

![]()

Labels: Industrial Engineering, Mechanical Engineering, Production Engineering

Monday, July 30, 2007

Toyota Production System

The credit of developing Toyota Production System goes to Taichi Ohno, former VP, Toyota Motor Corp and Shingo Shigo. Shingo was a thinker, who had the basic framework in his mind, and Ohno was implementer, who actually executed Shingo’s ideas. The system was developed and promoted by them while working for Toyota Motor Corporation. It is being adopted by many Japanese companies in the aftermath of 1973 oil shock. Though the main purpose of the system is to reduce costs, the system also helps increase the capital turnover ratio and improves the productivity of a company as a whole.Even during period of slow growth, the TPS could make a profit by decreasing costs in unique manner that is, by completely eliminating excessive inventory or workforce. It would probably not be overstating our case to say that is another revolutionary production system. It follows the Taylor system (scientific management) and the Ford system (mass assembly line).Basic Idea and FrameworkIts major focus is on completely eliminating unnecessary elements of production system, in order to reduce costs and to increase productivity.However cost reduction is the system’s major goal, but the other three it is ought to satisfy are :

- Quantity control- this arms the system to effectively deal with the fluctuations in demand.

- Quality Assurance- this ensures that each process supplies only good part to next process

- Respect for humanity- the most important element in the system is human being. Happy Worker = Happy Machine = Happy Factory = Happy Company = Increased Profit.

As can be seen in the diagram, the major pillars of this system are JIT and Autonomation. The other two key concepts to the TPS include Flexible Workforce that is multiskilled workforce, and Creative thinking or inventive ideas or capitalizing of worker suggestions.To realize these four concepts, Toyota has established the following systems and methods:

- Kanban system, which act as enabler for JIT

- Production smoothing method to adapt to demand changes

- Reducing Set up time in order to reduce the production lead time

- Standardization of operations to attain line balancing.

- Machine Layout and the multi-function worker for the flexible workforce concept

- Small group improvement activities to reduce the costs and improve the worker’s morale

Visual control system to achieve Autonomation concept - Functional Managements system to promote company wide quality control.

I have myself worked on the few concepts like Kanban, Set up Time reduction, Standardization of operations, Small group improvement activities, Machine Layout, small lot production. I will discuss all the elements of the diagram, in my series of coming articles. My suggestion is just click on the picture to see the full size image and understand the framework.Though while reading this article and seeing the diagram, you may think that this system is only relevant to manufacturing and specifically to assembly line. But, it is nowadays being used even in services and software companies. Only the names are different. Some know it as Lean Manufacturing System. Then most of the companies, while adopting this methodology and customizing it, gives it own name like Maruti calls it MPS ( Maruti Production System) and Subros calls it SPS (Subros Production System).Actually, I came in touch with this methodology in rookie year of my job. I was so fascinated by it, that I kept on bugging my HR and Top Management guys, till they didn’t sent me to actually see it happening in Toyota. And it was, simply mind blowing system. They actually practice, what we read. So, friends that’s all for now, keep reading for my next article on the critical elements of this System.

Posted by

Prabal Aggarwal

at

8:57 AM

25

comments

![]()

Labels: Industrial Engineering, Mechanical Engineering, Production Engineering

Monday, July 23, 2007

Hi

This is a blog which serves as a common platform for engineers across the globe to interact

Posted by

ViruS

at

12:28 AM

2

comments

![]()

1 comments:

Post a Comment