This is my second article of the series of Toyota Production System on this blog. I m not making it very elaborate and cumbersome. For more details there is lot of literature available on the net. My only objective in writing this article is to give the jist of the methodology and to share my experiences with the readers.

What is Kanban?

Kanban is a critical element of Toyota Production System, by acting as enabler to JIT. It was developed in Toyota Motor Corporation in Japan during 1950’s. Now it is a very popular tool in lean manufacturing.

Essentially, the most important role Kanban plays by enforcing and checking Pull System in manufacturing. Literal meaning of Kanban comes from Kan- card, Ban- signal. So, it’s a information system employing cards that enables and checks the usage of Pull System.

Pull & Push System

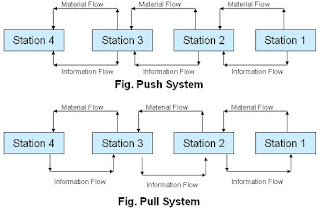

Without taking too much length of the article I will briefly explain Pull and Push System. Lets suppose there are four stations in an assembly line as shown in the fig’s. Station 1 is the first station and feeds material to the second station and so on.

In the pull system, the production schedule is given to the station 1. The station 1 accordingly makes the first component and pushes it to the station 2 and so on. In this way, along with the material flow station 1 is giving the information target also to the station 2, that how many components it needs to make.

In the push system, the production schedule is given to the station 4. the station 4 demands the number of components required from station 3 and so on. In this way the information is passed on from station 4 to station 3, that how many components it needs to make.

The push system is good when the certainty is the system is high, but normally its not so. Normally there is lot of uncertainties like change in demand, machine breakdowns, defective components, etc. This uncertainty leads to building up of inventory at every station. While in the case of pull system, actually the customer is driving the demand, by feeding the information of limited time period to the station 4. This enables the system to be flexible and more responsive to the market demands. The pull system, enforces that if one station is out of order then the whole line will stop example : if station 3 breaks down, then it won’t be able to supply to station 4 and it will stop and it won’t demand anything from station 2 and it will stop. This leads to reduced inventory at every step, which liberates the cost stuck in the inventories.

So, there should be a system that enables the pull system. Here Kanban comes into picture.

How Kanban works?

The simplest method used for Kanban is Dual Kanban. The elements of this system are :

- Production-ordering Kanban Card

- Withdrawal Kanban Card

- Kanban Post

A Production-ordering Kanban - specifies the kind and quantity of product which the preceding process must produce. The one illustrated (right) shows that the machining process SB-8 must produce the crankshaft for the car type SX50BC-150. The crankshaft produced should be placed at store F26-18. The production-ordering Kanban is often called an in-process Kanban or simply a production Kanban.

A Withdrawal Kanban - specifies the kind and quantity of product which a manufacturing process should withdraw from a preceding process. The withdrawal Kanban illustrated (right) shows that the preceding process which makes this part is forging, and the person carrying this Kanban from the subsequent process must go to position B-2 of the forging department to withdraw drive pinions. Each box of drive pinions contains 20 units and the shape of the box is `B'. This Kanban is the 4th of 8 issued. The item back number is an abbreviation of the item.

Kanban Post - Each process (area, cell) on the production line has two Kanban `post-boxes', one for withdrawal and one for production-ordering Kanbans.

Using Kanbans on a production line

At regular intervals a worker takes withdrawal Kanbans that have accumulated in his process post-box, and any empty pallets, to the location where finished parts (components, assemblies) from the preceding process are stored. Each full pallet has attached to it one or more production-ordering Kanbans which he removes and puts in the appropriate post-box belonging to the process that produced the parts. The worker now attaches a withdrawal Kanban to the pallet and takes it back to his own process area. When this new pallet begins to be used, its withdrawal Kanban is put back into the withdrawal post-box. At each process on the line, production-ordering Kanbans are periodically removed from their post-box and used to define what parts and quantities to produce next.

Enablers for Kanban are Quality Assurance and Production Smoothing as can be seen in this fig. If these things are not followed instead of becoming a boon to company Kanban becomes headache. I myself faced this problem when I designed Kanban System in one of the companies I worked for. But the moment I enforced Quality Assurance and Production Smoothing, the Kanban was able to play its meant role. I designed the system so that we are able to avoid the pilferation of material on the assembly lines. The pilferation, lead to inaccurate data punching in ERP software of SAP. The problem was that we were following push system. The worers were getting material more than required for the particular shift. This lead them to neglect the material falling on the shopfloor. The material which fell down was never picked by them, but by sweeper landing it to dustbins. So, actually the ERP was showing that the material of 100 assemblies was there, but it was of only 90. Now this inaccuracy of data, lead to backfire of whole Supply Chain. The stores were not aware that they are not storing enough material to support the production, so they didn’t order to vendors. Vendors didn’t knew that they have to produce this much supply components, so the vendor didn’t plan. But our customer has to be satiated at any cost. So, the result was use of defective parts, stealing parts from other lines, pressurizing vendors to produce more than its capacity. This chain of activities lead to the firefighting in all the related departments like PPC( Production Planning and Control), Production, Purchase, Stores, Vendors and so on. But the core reason was pilferage or push system. So, I proposed this to my company. And fortunately, I was given project to implement it. I studied around eight companies for designing it including Maruti Udyog Limited, Toyota, GE and others. Finally, when we implemented it, the results were simply mind blowing. I never thought that it could be so powerful. My only aim was short sited that is to check material pilferage. But the results were that the inventory of 48 hours on shop floor got reduced to 4 hours, production doubled, manpower was cut by 25 %, production incharge who earlier was always fighting for material on shopfloor didn’t need to go to shop floor for a week. This was one of the major turning point in my life. And I came to understand and appreciate the power of Toyota Production System or Lean Manufacturing and till now directly or indirectly I m pursuing career in it.

I hope the article would be helpful to the readers. Wait for next article of the series by me.

0 comments:

Post a Comment